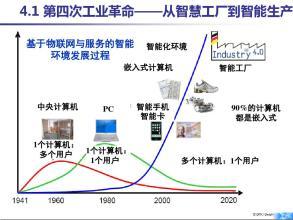

Industry 4.0, the fourth industrial revolution, is the most concerned topic in current manufacturing. The industry, academia and government have issued a series of clear planning and policy packages, including the German “Industry 4.0 Project”, the US “Industrial Internet”, and the Chinese government’s “Made in China 2025” plan. Industry 4.0 is expected to take shape in about 10 years, which will bring subversive model changes to manufacturing automation. Automation will be expanded from production line to full value chain to realize automatic configuration of production, supply chain and human resources.

"Internet +" has spawned nearly one trillion market for domestic industrial automation

Industrial automation involves a long-term industrial chain, and the domestic market is nearly one trillion. The "Internet +" brings accelerated growth. According to the statistics of the German Industry 4.0 Working Group, the scale of China's automation market in 2012 has reached 800 billion yuan (100 billion euros), ranking first in the world with 29%. Industrial automation entered the post-digital era, and the Internet is the catalyst for Industry 4.0. In the process of Industry 4.0, on the one hand, traditional automation will be further popularized, such as the numerical control rate of key processes will increase from 33% in 2015 to 64% in 2025; on the other hand, emerging applications such as industrial clouds and robots related to Internet and collaborative manufacturing Rapid development, effectively driving the overall industrial automation market.

According to market segmentation, we divide the industrial automation industry chain into seven sub-sections.

1) Motion Control and Robot: Servo and CNC are the most well-known products;

2) Industrial software: including MES, PLM and other production line management systems and optimization software such as simulation and advanced control;

3) Monitoring system: mainly DCS and PLC, in some cases, it will also be realized by single chip or IPC;

4) Sensing and testing: including various sensors, transmitters and testing instruments, is the eye and nerve endings of industrial systems.

5) Variable frequency drive: The frequency converter is the device that drives the motor to realize the speed and power conversion. Under the precision and torque demand of the servo, the speed and steering of the equipment can be adjusted to achieve energy saving;

6) Internet +: including emerging technologies such as industrial cloud, industrial big data, industrial control network security and the next generation of industrial control systems;

7) Others: Contains relatively loose products such as control valves and contactors.

Stable growth in demand + import substitution: the driving force behind the high growth of China's industrial automation enterprises. According to the statistics of the industrial control network, the localization rate of China's automation market is less than 40%, and precision products such as PLCs and sensors are less than 20%. Import substitution has kept Chinese companies above-average growth. Using the same technology of power electronics and electrical control, local leading companies are rapidly deploying in emerging fields such as electric vehicles, robots, and intelligent manufacturing to achieve new profit growth points. In 2014, the market scale of China's industrial automation representative products has reached 150 billion, and it is expected to maintain a compound growth rate of more than 12% in the future. Chinese companies will benefit from import substitution in the long run, and the profit of local leading listed companies is expected to maintain a compound growth rate of more than 20% in the future.

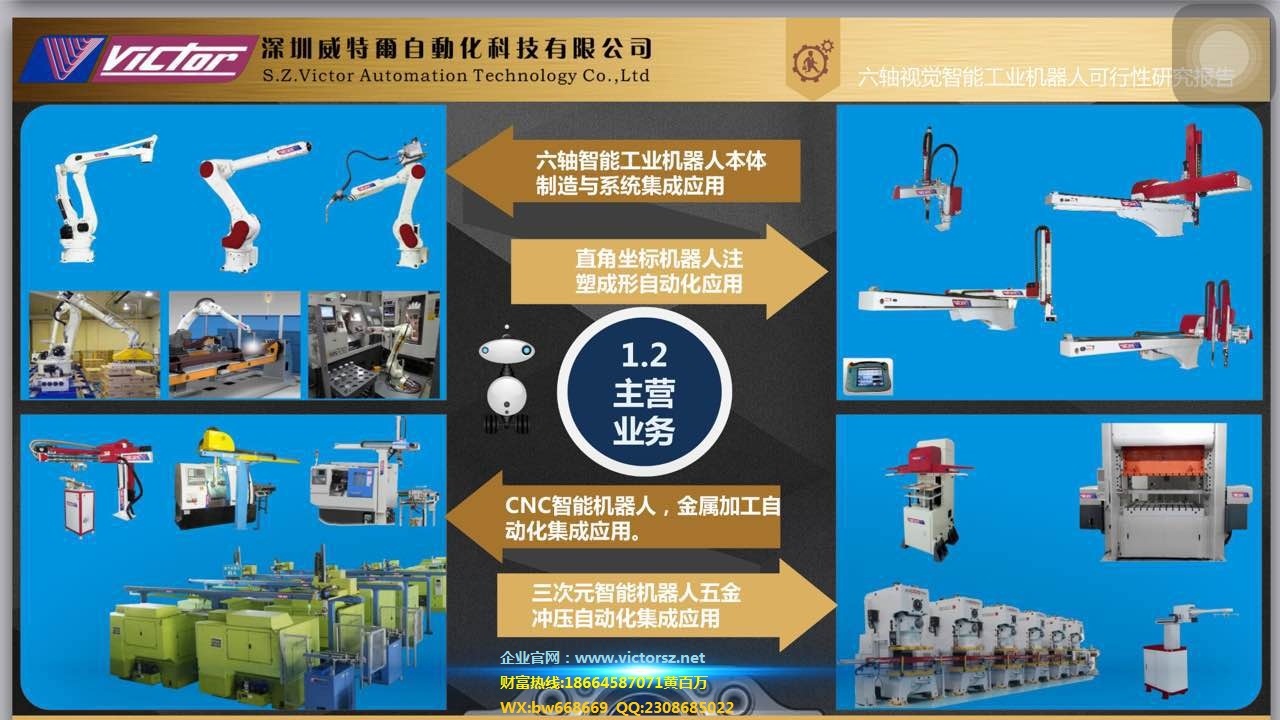

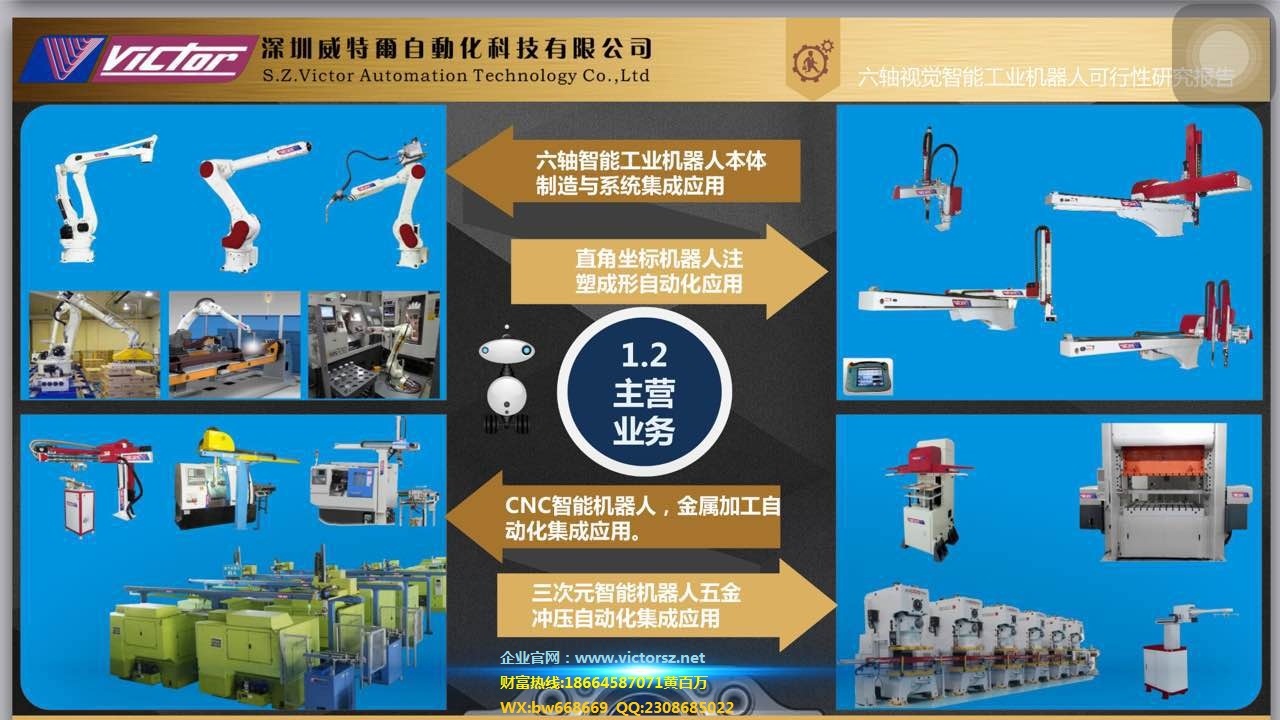

Victor(Industrial Robot) - Dedicated to building a domestic "Industrial 4.0 Automation" and "Smart Factory" one-stop service! Main: injection molding machine special manipulator, CNC manipulator, metal punching manipulator, fuel injection robot, welding manipulator, assembly manipulator and custom-made non-standard automatic mechanical equipment! Find global partnerships and entrepreneurial partners!

![[Pu Daxi Ben] - Weitel Robot Project won 600,000 yuan from Shenzhen Science and Technology Commission [Pu Daxi Ben] - Weitel Robot Project won 600,000 yuan from Shenzhen Science and Technology Commission](https://omo-oss-image.thefastimg.com/portal-saas/new2023041417545479371/cms/image/4f67a616-22b8-4e42-80fb-0188250e15d4.png)