OFweek Robot Network News: In 2016, the German Robotics and Automation Technology Trade Fair was held in Munich today. The exhibition covered many fields such as robotic industrial production lines and commercial robots. It has become the world's largest robot industry and automation technology expo event. The exhibition will also integrate the innovation of automation technology production and scientific research, share the most advanced robot technology and scientific and technological achievements, and further promote the rapid development of industrial automation and robot parts industry.

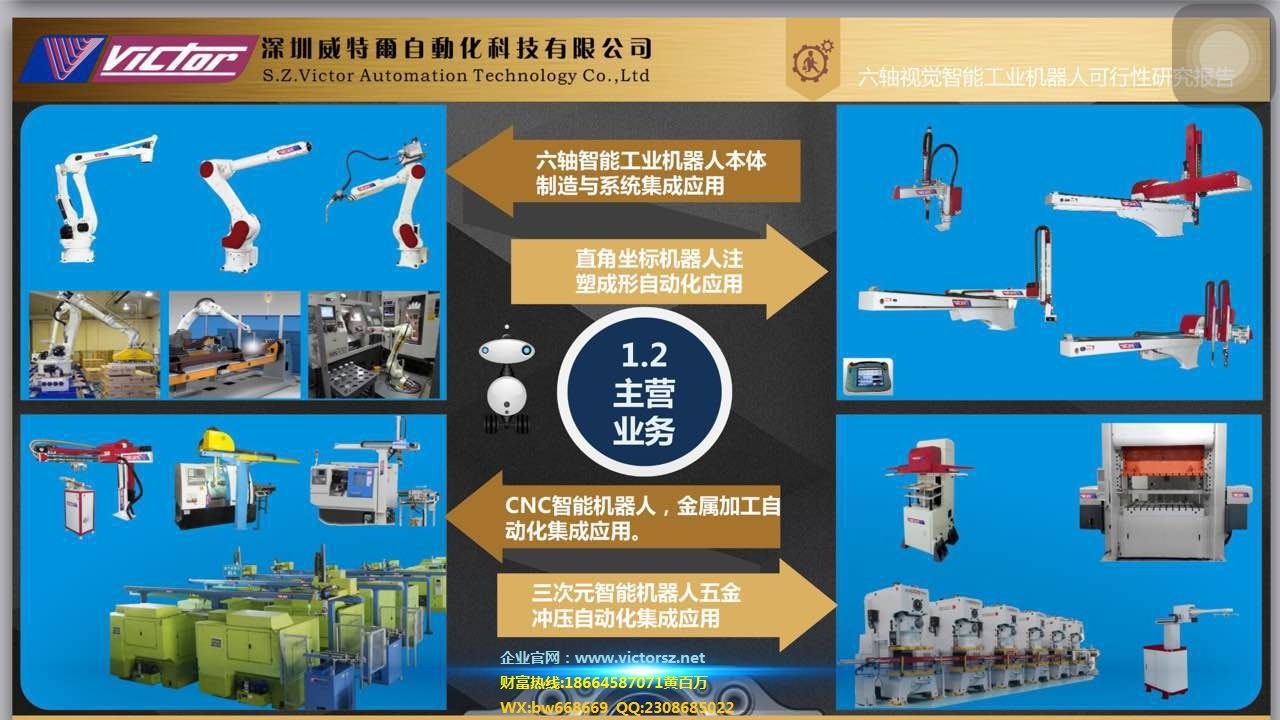

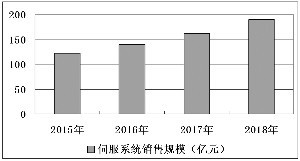

Industrial robot control systems and automation products mainly involve servo motors, reducers, controllers and sensors. As an important part of industrial automation, servo system is mainly used to accurately follow or reproduce the feedback control system of a certain process. The servo system enables the output control of the position, orientation, and state of the object to be controlled, and can follow the automatic control system whose input target is arbitrarily changed. The servo system is divided into hydraulic servo system, electric servo system and pneumatic servo system according to different actuators. Servo systems are widely used in machine tool, textile, printing and packaging machinery. At the same time, with the rapid expansion of industrial robots and electronic manufacturing equipment in recent years, the application scale of servo systems in emerging industries will also accelerate.

At present, the joint drive of the robot is inseparable from the servo system. The more joints, the higher the flexibility and precision of the robot, and the more servo motors are used. The robot has higher requirements on the servo system, and must meet the requirements of fast response, high starting torque, large dynamic torque inertia ratio, wide speed range, and adapt to the shape of the robot to achieve small size, light weight, acceleration and deceleration, etc. And requires high reliability and stability. At present, industrial robots use more AC servo systems.

Servo system costs account for up to 24% of industrial robots, second only to reducers. In recent years, with the improvement of the level of industrial automation and the popularization of robot technology, the servo system will be increased as the sales of robots continue to increase. According to statistics from the China Robotics Industry Alliance, sales of domestic industrial robots continued to grow last year, with a total sales of 22,257 units, an increase of 31.3% over the previous year. Among them, the sales of domestic multi-joint robots accelerated, with sales exceeding 6,000 units, an increase of 71.7% year-on-year, accounting for 27.4% of the total sales of domestic industrial robots, an increase of 6.4 percentage points over the previous year. The sales volume of factory logistics robots exceeded 1,700 units, a year-on-year growth rate of 93.7%, an increase of 2.6 percentage points over the previous year. Coordinate robots are still the main models of domestic industrial robots. Last year, the sales volume was nearly 10,600 units, accounting for 47.6% of the total robot sales.

From the perspective of market share, the current market share of foreign servo companies in China is 75%. Among them, Japanese brands accounted for 50%; European and American brands accounted for 25%. Domestic brands only account for about 20% of the market. At present, China's low-end and mid-range servo systems have been able to achieve mass production, but high-end servo systems have not yet formed commercial and mass production capacity. Domestic demand for precision servo motor control systems mainly depends on imports. With the promotion of the robot industry and the continuous improvement of domestic servo technology, the pace of import substitution of servo systems in China will accelerate.

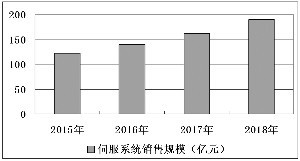

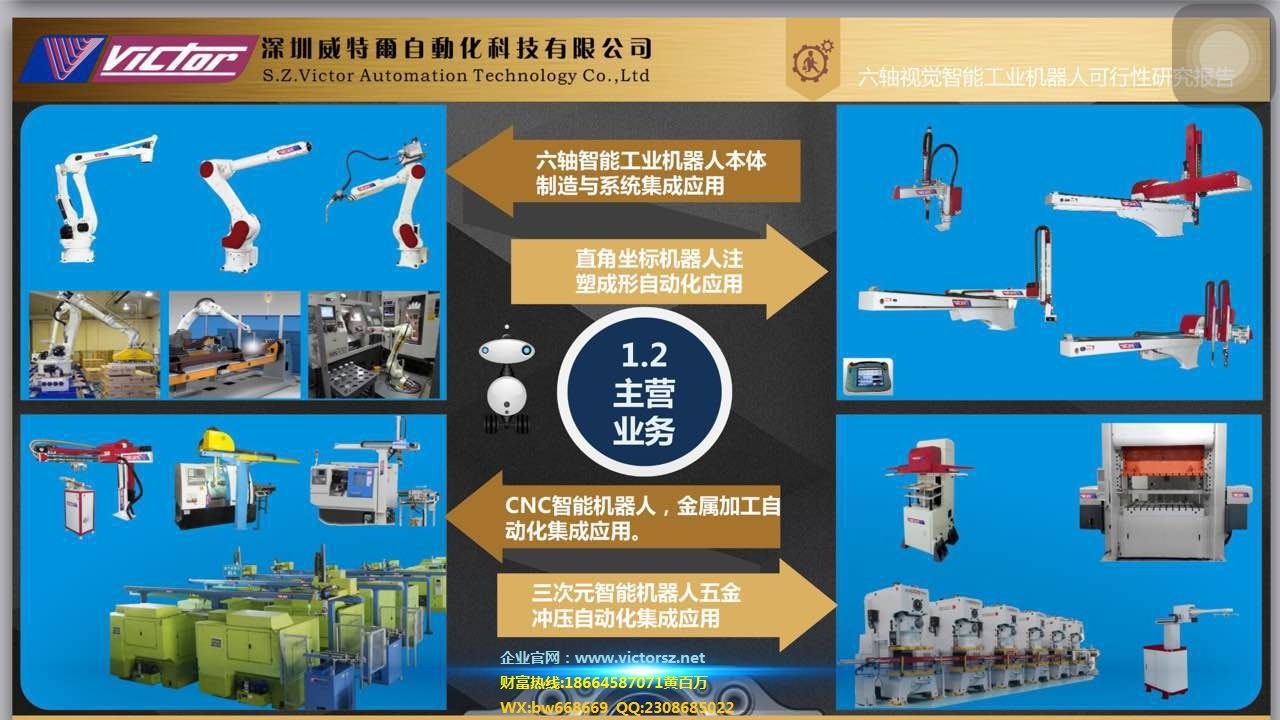

Victor (Industrial Robot) - Dedicated to building a domestic "Industrial 4.0 Automation" and "Smart Factory" one-stop service! Main: injection molding machine special manipulator, CNC manipulator, metal punching manipulator, fuel injection robot, welding manipulator, assembly manipulator and custom-made non-standard automatic mechanical equipment! Find global partnerships and entrepreneurial partners!