News

Robots let Chinese manufacturing fight the US and India?

Release time:

2019/03/14

|

Industrial robots for welding operations "Danger": production efficiency, energy prices can not be beautiful; labor costs are not rivalry in Indonesia

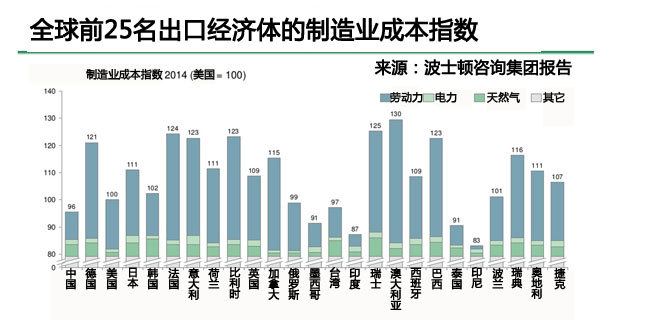

The Boston Consulting Group's Manufacturing Cost Index reflects that China's manufacturing can no longer rely on labor cost advantages

The rise in labor costs threatens China's “world factory” status is also a common problem. Generally speaking, it comes from two aspects: First, the reduction of the labor force is a trend. At the beginning of 2013, Ma Jiantang, the director of the National Bureau of Statistics, admitted for the first time in public. China's population and labor supply patterns have changed. This is the first decline in the absolute number of working-age people in China for quite a long time. He said, "The absolute number of working-age people has decreased by 3.45 million in 2012." Second, the younger generation of workers is more mobile and the welfare requirements for work are much higher than the previous generation. Many companies are suffering from "not good management." . .

As a result, some foreign companies moved to Indonesia to go to Indonesia, and some state-owned enterprises went to the United States to set up factories. Isn't China's "world factory" status unprotected?

Haier layoffs are said to be related to robots Robots are much more labor intensive. An intuitive example is that a company in Foshan uses robots for welding operations. The head of the company's technical department said, “At present, a robot can weld more than one product at the same time, which is equivalent to the workload of the original 2-4 people. The efficiency is 2.5 times the original." After the Haier layoffs, a reporter interviewed a number of home appliance companies, and found that these famous Chinese home appliance manufacturers almost all introduced robots to work, and they are very sure of robots. effectiveness. Moreover, with the quantitative production and use of robots, their own costs are also falling, even faster than estimated. A motor company said that each small multi-joint robot can replace the workload of two workers and recover the cost within two years. And five years ago, it took three to four years to recover the cost. Contrary to the increase in labor costs, the recovery time of robot costs is shortening, which will also promote the popularity of robots.

The right medicine 2: Treat the treatment of a new generation of workers - operating robots is a "cool" job for young people

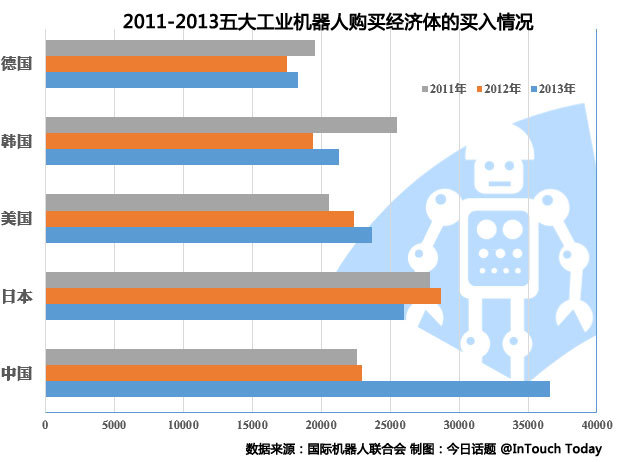

Since it is a panacea for the two major problems, China has become the number one buyer.

The number of industrial robots purchased in China has become the first in Japan in the past year.

However, when robots defended and upgraded the status of the world's factories, they also brought two major "human" problems.

Workers and robots work together

Indeed, people's expectation for robots is to give those who are dirty and lively and mechanically good to the robots, and the liberated human beings are engaged in more high-end jobs, not so tired, with higher technical content and happiness. The index is also higher. However, if education does not win the technology, then everything is futile. At present, the total number of robots introduced in China is not large. Many enterprises have also encountered recruitment problems. Our education has not yet cultivated enough corresponding talents. Of course, at present, the promotion policy of vocational education is a good thing, but it still makes some education experts worry that these vocational schools are administrative-oriented rather than market-oriented and employment-oriented, and can not cultivate the people who need the market. …[detailed]

Assignment puzzle: income distribution may be more disparate, how to make more people enjoy the benefits of the upgraded world factory is a big question

The high productivity of the robot means that many people will be eliminated. At the same time, according to the current domestic experience, in addition to senior technicians, robots also need ordinary workers to cooperate with the operation, but this work is extremely low in technical content, and two days of training can be employed, and the replacement is almost 100%. These situations mean lower incomes or unemployment difficulties for low-skilled workers, and this group is not small. The ideal state, of course, is the director of the German Labor Institute (IZA). "The Chinese government wants to see a rise in salary levels, not only to promote domestic consumption, but also because it means that Chinese companies are global. The market produces more advanced products. Operating large-scale assembly plants is no longer seen as a viable way to ensure the future of China's economy. In order to achieve its goals, China needs well-trained, well-paid and highly motivated workers. Robots are used for heavy and low-level Work is in line with this strategy."

But ideals are ideal, and whether the popularity of robots makes poorer poor people poorer is also a hot topic worldwide. Two American university scholars believe that the improvement of productivity may make the situation of future generations worse. Workers are replaced by robots, and their income will be transferred to the owners of robots, most of whom will be “retired” and their deposits will be less than younger. The investment in human capital will be reduced because young people can no longer bear the associated costs; investment in machinery will also be reduced, as the size of the savings in the economy as a whole will also shrink.

In other words, the result of technology and social development is to allow only some people to enjoy and widen the gap between the rich and the poor, or to allow most people to share a piece of cake is a major issue after the robot is widely used, and this involves Social security and employment skills training for low-income, low-skilled or unemployed people.

|

Related news

2019-03-14

2019-03-14

![[Pu Daxi Ben] - Weitel Robot Project won 600,000 yuan from Shenzhen Science and Technology Commission [Pu Daxi Ben] - Weitel Robot Project won 600,000 yuan from Shenzhen Science and Technology Commission](https://omo-oss-image.thefastimg.com/portal-saas/new2023041417545479371/cms/image/4f67a616-22b8-4e42-80fb-0188250e15d4.png)