Products

Plastic Molding Series--Five Axis Servo Manipulator

Either now or in the future,are suitable for injection molding machine automation Perfect end configuration requirements,industry”wisdom”made, to begin.

Category:

Plastic Molding Robot

Key words:

Plastic Molding Robot

Detail

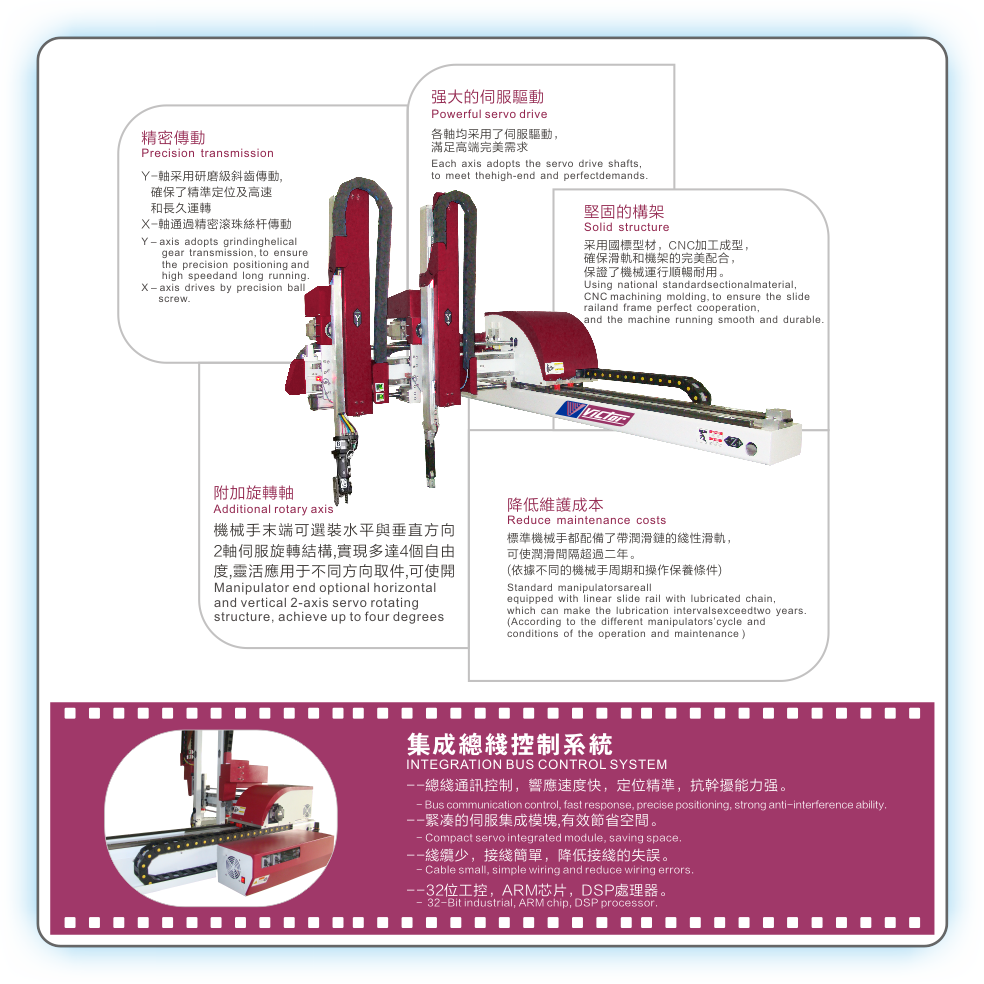

Plastic molding series--five axis servo manipulator

Either now or in the future,are suitable for injection molding machine automation Perfect end configuration requirements,industry”wisdom”made, to begin.

-Are used for each axis servo motor drives,intelligent control,precise operation.

-Arm times velocity structure design, to realize the high speed running.

-Lightweight extruded aluminum frame type,to reduce the weight of the moving parts,and achieve the best plus/minus velocity.

-High-performance servo drive and all axis linear slide rail realized high speed movement and the shortest pick-up time.

-This series can used to controlthe complex peripherals of I/O modules,facilitate stacking,sorting,insert and other additional functions.

人机介面

威特尔(victor)VH系列的全伺服高端智能机械手,该产品采用总线通讯控制系统,响应速度快,定位精准、抗干扰能力强,并可以通过以太网接口连接互联网与手机客户端,实现远程监控、编程等人机互动,轻松地完成更多复杂工作。系统不配备多种IO接口,可以拓展视觉IML、 CCD等上下游辅助设备的控制功能,实现自动上料,模内镶件埋入、模内贴标、产品取件、堆叠打包、剪切水口、连接通电检测等一系列全自动化无人作业,帮助客户节省用工成本、节约生产空间,减少对环境、人体的危害,提高生产效率,在橡胶塑料工业中发挥最大潜能,从而达到最高工作效率与经济效益。