Products

Plastic molding series--the high-speed three-axis servo robot

Lightweight,simple structure,with fast response bus control system,can am arcs actions to achieve ultra-high-speed operation of the robot, allowing the in -mold period is less than 0.75secinds cycle time is less than 3.0s seconds for thin-wall molding High-speed pickup and other rapid application.

Category:

Plastic Molding Robot

Key words:

Plastic Molding Robot

Detail

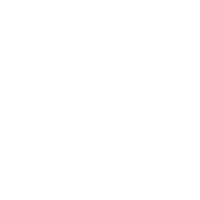

Plastic molding series--the high-speed three-axis servo robot

Lightweight,simple structure,with fast response bus control system,can am arcs actions to achieve ultra-high-speed operation of the robot, allowing the in -mold period is less than 0.75secinds cycle time is less than 3.0s seconds for thin-wall molding High-speed pickup and other rapid application.

-Each axis by servo motor drive, intelligent control and precise operation.

-Arm speed structure designed to achieve high speed.

-Original automatic grease lubrication system ensures adequate lubrication slide,down at the end of wear,

Easy maintenance and prolong life.

-Lightweight aluminum extrusion frame,to reduce the weight of moving parts to achieve the best acceleration/deceleration.

-High performance servo drives and linear rails on all axes to achieve a high-speed motion and pick the shortest time.

-The series can be expanded to control complex peripheral I/O modules,easy to stack,sort,insert a number of additional features.

The Man-machine Interface

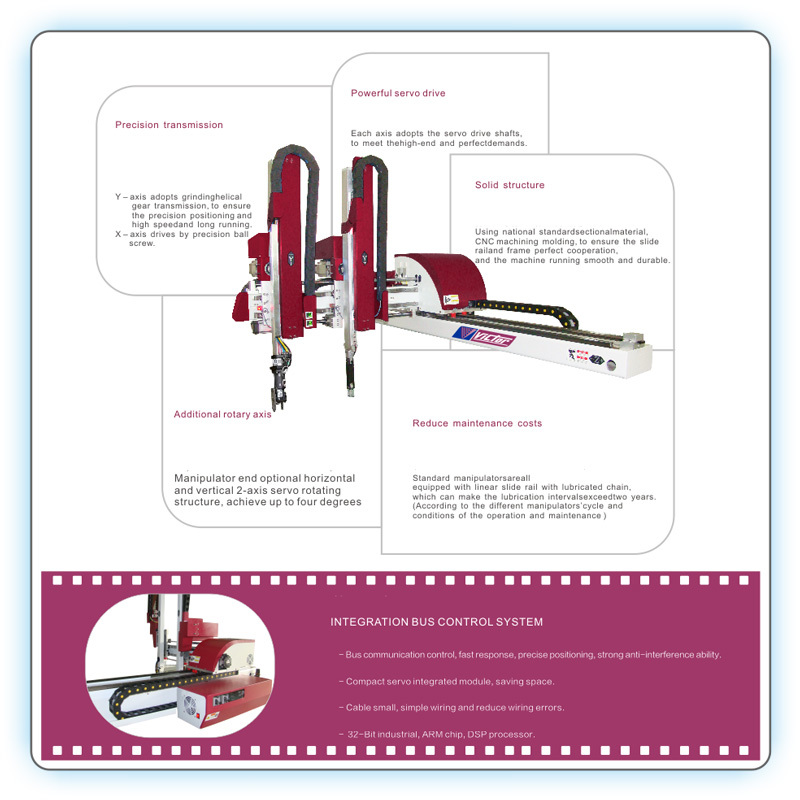

Product advantages

-Training time is short and program is easy to learn,including movement,process,time setting and formed interface.

-Real-time fault detection and prompt, integrated I/O display

-The system is security and reliable, reminding when operation system made by mistake.

-A7.5-inch LCD screen(touch and buttons)

-It canrealize circular arc interpolation and linear interpolation,save pick-up time

-It can realizemulti-point picking up in intramode

-It can realize the current program storage,save the time of adjustment.

-Support multiple languages (Chinese,Traditional Chinese character,English,Japanese,Korean,Thai)

-it has completed operation pattern,can stackable,arrangement,packing,free placement,external shear

-One-step operation function,can single step by step into the debugging.

-It can completely diagnostic text errors and time recording

The full-servo high-speed manipulator of the VH series adopts the bus communication control system, which has fast response speed, accurate positioning and strong anti-interference ability. It can realize ultra-high speed operation of the robot, allowing the in-mold time of less than 1 second, and With a cycle time of less than 5 seconds, it can be used for fast applications such as high-speed pick-up of thin-walled products. It can connect to the Internet and mobile client through the Ethernet interface, realize remote monitoring, programming and other human-computer interaction, and easily complete more complicated work. The system is not equipped with a variety of IO interfaces, which can expand the control functions of upstream and downstream auxiliary equipment such as visual IML and CCD, and realize automatic feeding, in-mold insert embedding, in-mold labeling, product pick-up, stacking and packing, and cutting nozzle. A series of fully automated unmanned operations such as connection power-on detection help customers save labor costs and save production space, thereby reducing environmental and human hazards and improving production efficiency and economic benefits.