Products

Plastic molding series--Large Tau triaxial servo manipulator

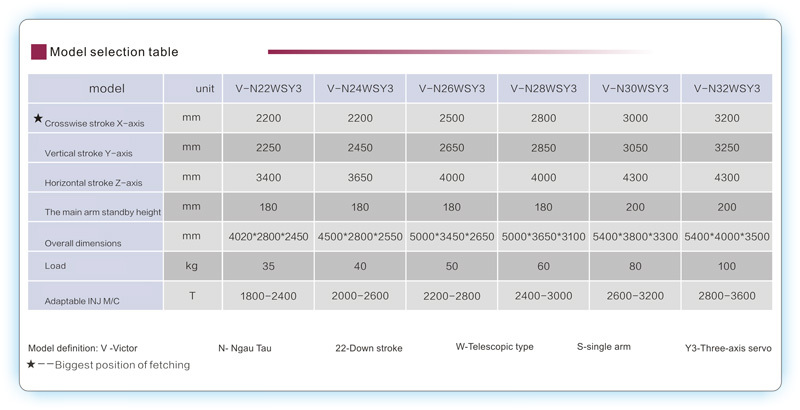

Specially designed for large injection molding machine, can be used for clamping force up to 2000-4000,it is preferred for the automotive industry automation.

Category:

Plastic Molding Robot

Key words:

Plastic Molding Robot

Detail

Plastic molding series--Large Tau triaxial servo manipulator

Specially designed for large injection molding machine, can be used for clamping force up to 2000-4000,it is preferred for the automotive industry automation.

-Open(Tau) structure,full servo drive to meet the flexible,precise application requirements.

-For heavy- duty products designed for clamping force 1000-4000T large injection

Molding machine can remove the product 50-100KG.

-The end of the robot arm using two-axis servo drives,product withdrawal can be rotated 360degrees to achieve a variety of special application requirements.

The Man-machine Interface

Product advantages

-Training time is short and program is easy to learn,including movement,process,time setting and formed interface.

-Real-time fault detection and prompt, integrated I/O display

-The system is security and reliable, reminding when operation system made by mistake.

-A7.5-inch LCD screen(touch and buttons)

-It canrealize circular arc interpolation and linear interpolation,save pick-up time

-It can realizemulti-point picking up in intramode

-It can realize the current program storage,save the time of adjustment.

-Support multiple languages (Chinese,Traditional Chinese character,English,Japanese,Korean,Thai)

-it has completed operation pattern,can stackable,arrangement,packing,free placement,external shear

-One-step operation function,can single step by step into the debugging.

-It can completely diagnostic text errors and time recording

The full-servo high-end intelligent manipulator of the Victor VH series adopts the bus communication control system, which has fast response, accurate positioning and strong anti-interference ability. It can connect to the Internet and mobile client through the Ethernet interface to realize remote operation. Monitoring, programming and other human-computer interactions make it easier to do more complex work. The system is not equipped with a variety of IO interfaces, which can expand the control functions of upstream and downstream auxiliary equipment such as visual IML and CCD, and realize automatic feeding, in-mold insert embedding, in-mold labeling, product pick-up, stacking and packing, and cutting nozzle. A series of fully automated unmanned operations such as power-on detection, helping customers save labor costs, save production space, reduce environmental and human hazards, improve production efficiency, and maximize their potential in the rubber and plastics industry to achieve maximum efficiency. Economic benefits.