Products

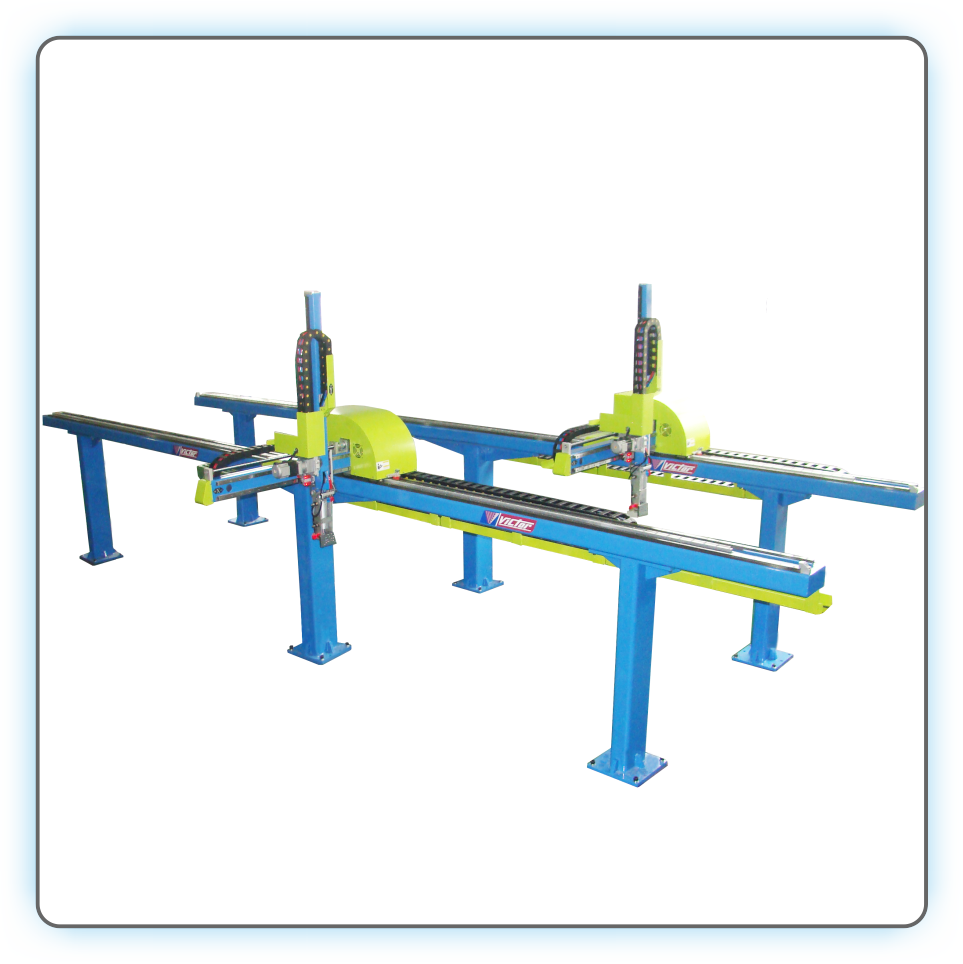

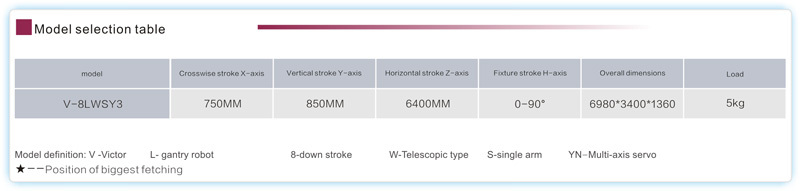

Metalworking series--CNC multi-station parallel manipulators

In multi-position parallel manipulators unmanned workshop organized overall solution, efficient,stable,economical,not land,”to all customers,”the new concept thus reflected.

Category:

CNC Machining Robot

Key words:

CNC Machining Robot

Detail

Metalworking series--CNC multi-station parallel manipulators

In multi-position parallel manipulators unmanned workshop organized overall solution, efficient,stable,economical,not land,”to all customers,”the new concept thus reflected.

-Gantry body structure design ,loading and unloading from the top,saving floor space and improve equipment operating efficiency.

-Are used for each axis servo drive, equipped with advanced communication bus control system, anti-interference ability,it can provide a variety of I/O modules and capabilities for integrated peripherals, implementation artifacts capture,loading,unloading,clamping,step conversion, online testing,tool management,self-lubricating,and other enhancements.

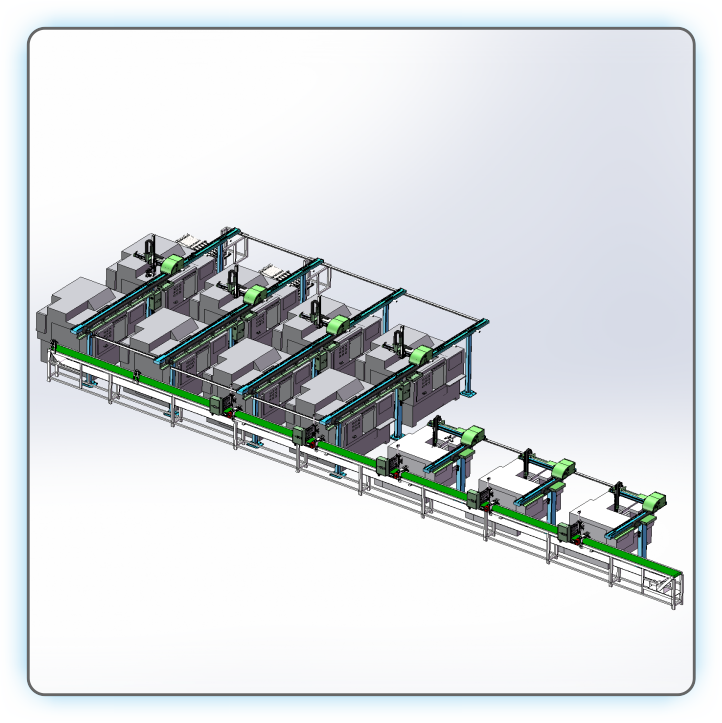

-Flexible configuration,according to the product processing technology,using multiple combinations of CNC and robot and an auxiliary switching mechanism into a streamlined automated production line ,truly no one workshop.

The Man-machine Interface

Product advantages

-Training time is short and program is easy to learn,including movement,process,time setting and formed interface.

-Real-time fault detection and prompt, integrated I/O display

-The system is security and reliable, reminding when operation system made by mistake.

-A7.5-inch LCD screen(touch and buttons)

-It canrealize circular arc interpolation and linear interpolation,save pick-up time

-It can realizemulti-point picking up in intramode

-It can realize the current program storage,save the time of adjustment.

-Support multiple languages (Chinese,Traditional Chinese character,English,Japanese,Korean,Thai)

-it has completed operation pattern,can stackable,arrangement,packing,free placement,external shear

-One-step operation function,can single step by step into the debugging.

-It can completely diagnostic text errors and time recording

Victor full servo intelligent CNC manipulator, using bus communication control system, fast response, accurate positioning, strong anti-interference ability, and can connect to the Internet and mobile phone client through Ethernet interface, realize remote monitoring, programming, etc. Machine interaction makes it easy to do more complex work. The system is also equipped with a variety of IO interfaces, which can expand the control functions of upstream and downstream auxiliary equipment such as visual IML and CCD, and realize a series of fully automated unmanned operations such as automatic feeding, product pick-up, stacking and packaging, and connection power-on detection, helping customers to save. Labor costs, saving production space, reducing environmental and human hazards, improving production efficiency, and maximizing potential in metal processing to achieve maximum efficiency.