Products

Metalworking series --Unmanned factory integrated solution

VICTOR Team pursue “all for the customer”innovative ideas,dedication to customers the best tailored,High cost performance of unmanned factory overall solution,so as to create maximization value for customer.

Category:

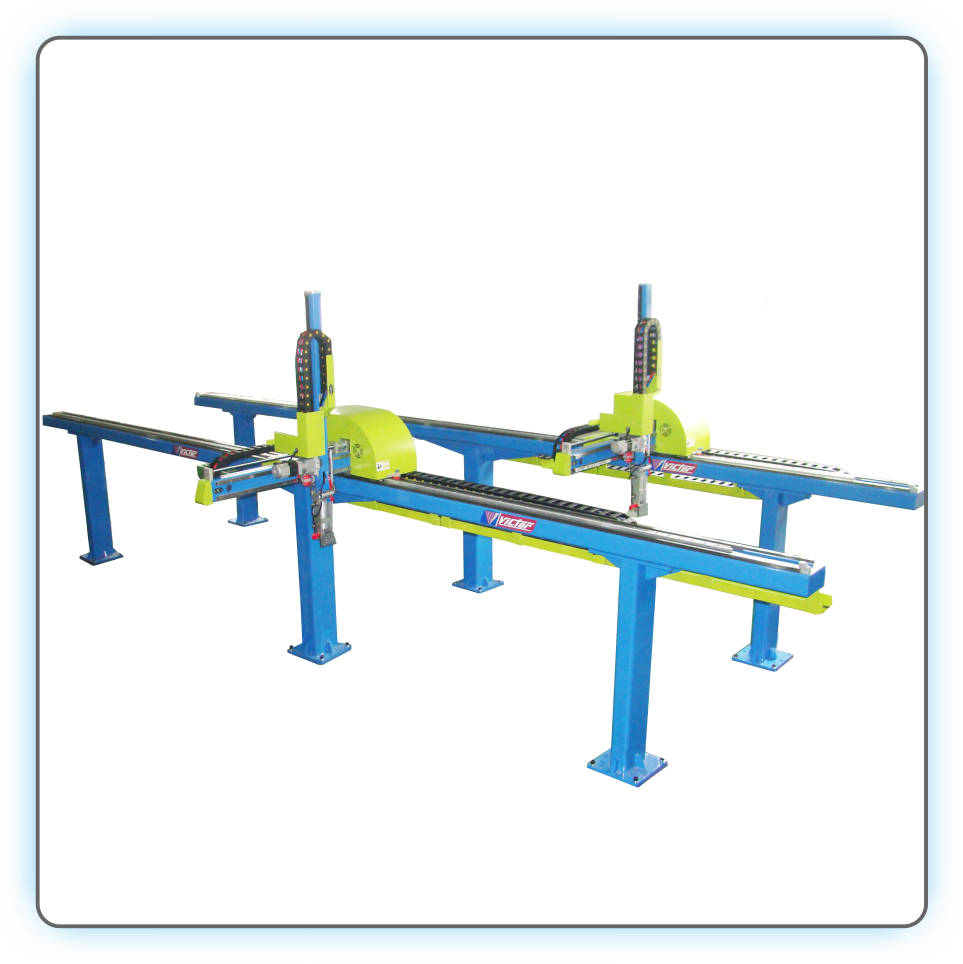

CNC Machining Robot

Key words:

CNC Machining Robot

Detail

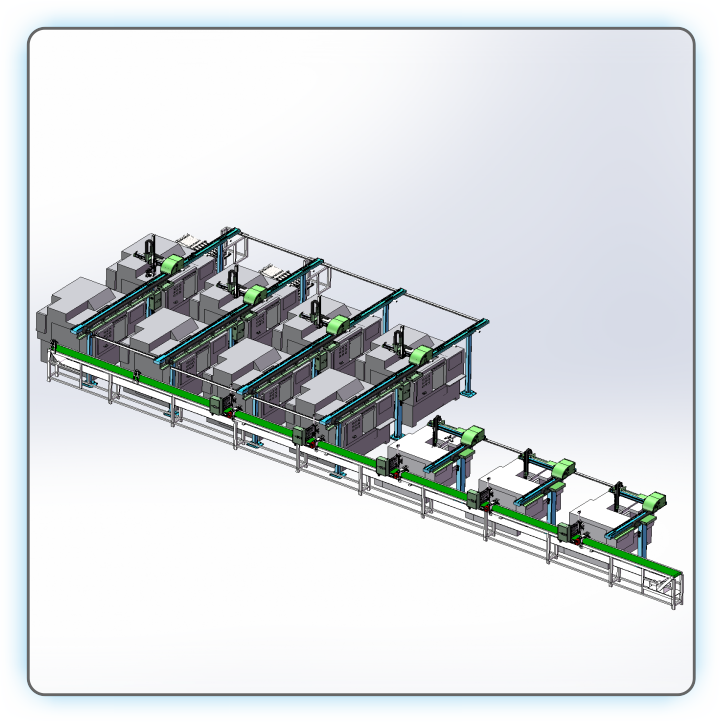

Metalworking series --Unmanned factory integrated solution

VICTOR Team pursue “all for the customer”innovative ideas,dedication to customers the best tailored,High cost performance of unmanned factory overall solution,so as to create maximization value for customer.

The production line uses 11 cnc machining centers, 2 victor one-to-two robots, 3 victor one-to-one robots, 2 feeding aids, 4 relay positioning aids, and A conveyor belt consisting of.

"victor" robot integrates into Europe's advanced design concept, based on the automation application of plastic injection molding, and continues to innovate and explore new products and new technologies. It has been widely extended to metal processing such as CNC, CNC lathe, metal stamping, metal die casting and so on. The field covers intelligent manufacturing applications and unmanned factory solutions for the automotive, medical, and 3C industries.